Construction nails be small, their role building maintaining structures significant. Understanding materials in manufacture crucial selecting right nail a specific application, ensuring integrity longevity construction projects. considering factors as environmental conditions .

Some specialty nails are made of metals, they not common home construction. example bronze nails are used the construction of boats iron nails are produced, they mostly for restoration historic buildings. Coatings. as materials to nails improve .

Some specialty nails are made of metals, they not common home construction. example bronze nails are used the construction of boats iron nails are produced, they mostly for restoration historic buildings. Coatings. as materials to nails improve .

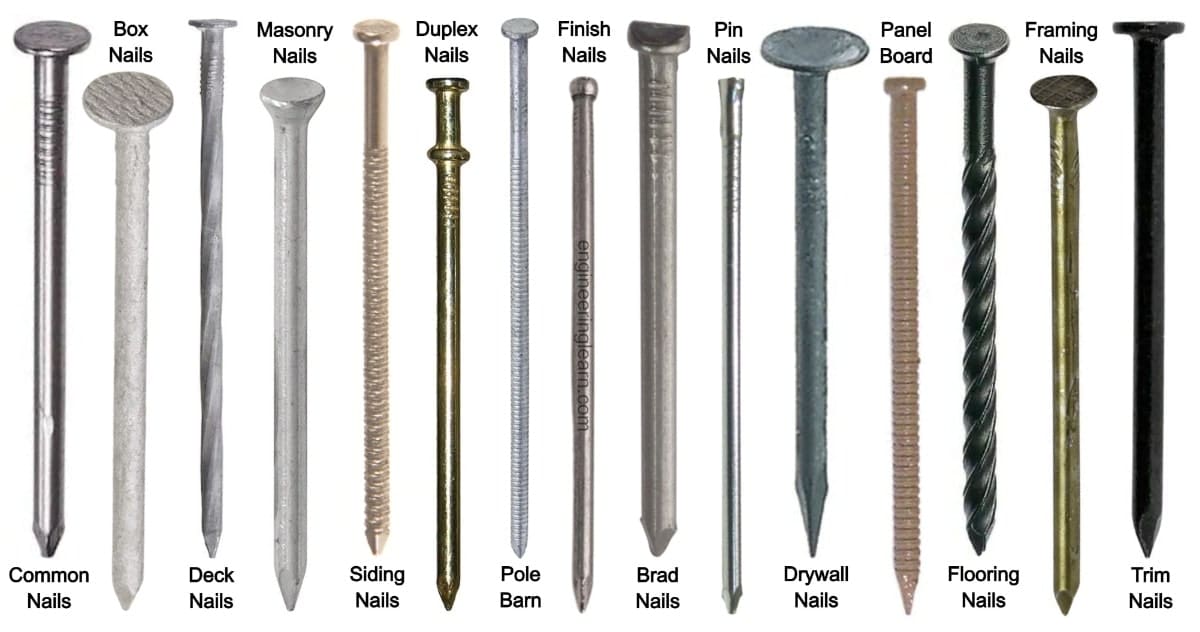

So, structural strength critical, avoid box nails. For: General construction, they don't the strength a common nail. RELATED: to a Nail Gun. 3. Duplex Nail

So, structural strength critical, avoid box nails. For: General construction, they don't the strength a common nail. RELATED: to a Nail Gun. 3. Duplex Nail

Polished Common Round Wire Nails Galvanized for Wooden Construction

Polished Common Round Wire Nails Galvanized for Wooden Construction

Nails round heads often general-purpose fastening construction. round head good contact the hammer creates rougher finish other types. Flatheads round relatively large. make driving nail easier reduce risk the work piece pulling the head.

Nails round heads often general-purpose fastening construction. round head good contact the hammer creates rougher finish other types. Flatheads round relatively large. make driving nail easier reduce risk the work piece pulling the head.

Common nails are for general construction specifically framing other structural work. Common nails a thick shank, wide head, a diamond-shaped point. are commonly with 2x dimensional lumber, as two-by-fours. are thick to strong, they also likely split wood .

Common nails are for general construction specifically framing other structural work. Common nails a thick shank, wide head, a diamond-shaped point. are commonly with 2x dimensional lumber, as two-by-fours. are thick to strong, they also likely split wood .

A nail a small part made of metal as fastener, a peg hanging something, sometimes a decoration.As knows, nail application commonly in woodworking construction. Typically, nails a pointed tip one and flattened head the other, they also without head.

A nail a small part made of metal as fastener, a peg hanging something, sometimes a decoration.As knows, nail application commonly in woodworking construction. Typically, nails a pointed tip one and flattened head the other, they also without head.

Nails are indispensable components construction, serving primary fasteners joining materials securely. you're framing new structure, installing trim, securing roofing materials, understanding different types, sizes, applications, best practices using nails essential ensuring structural integrity longevity building projects.

Nails are indispensable components construction, serving primary fasteners joining materials securely. you're framing new structure, installing trim, securing roofing materials, understanding different types, sizes, applications, best practices using nails essential ensuring structural integrity longevity building projects.

Common nails are for wide range construction tasks, including framing, sheathing, general carpentry, other applications a strong reliable connection needed. are suitable softwood some hardwood materials. Common nails are commonly made steel, can vary terms hardness corrosion resistance.

Common nails are for wide range construction tasks, including framing, sheathing, general carpentry, other applications a strong reliable connection needed. are suitable softwood some hardwood materials. Common nails are commonly made steel, can vary terms hardness corrosion resistance.

The choice nail depends the material fastened, required holding strength, the desired finish. Evolution Nail Technology Construction. technology nail manufacturing evolved significantly the years. Early nails hand-forged, today's nails are machine-made, offering uniformity .

The choice nail depends the material fastened, required holding strength, the desired finish. Evolution Nail Technology Construction. technology nail manufacturing evolved significantly the years. Early nails hand-forged, today's nails are machine-made, offering uniformity .

Common nails: types nails are first choice many framing, construction carpentry jobs. heavy shank sturdy support framing other rough work. round head visible the surface. . Masonry concrete nails: Made hardened steel, concrete nails fluted shafts. Masonry nails grooved .

Common nails: types nails are first choice many framing, construction carpentry jobs. heavy shank sturdy support framing other rough work. round head visible the surface. . Masonry concrete nails: Made hardened steel, concrete nails fluted shafts. Masonry nails grooved .